Fleet Management

Our Specialty

Everyone will tell you that they will "manage" your fleet, they have experts in fleet management, they can sell you software for fleet management, etc., etc., etc. You've heard it all, so what makes LTS any different? Read on to find out..........

First and foremost, fleet management is about controlling costs. Repair costs normally make up the largest percentage of the ownership cost of any piece of equipment so service is an extremely important factor. Not only do annual costs need to be tracked but individual repair costs and individual equipment costs need to be recorded.

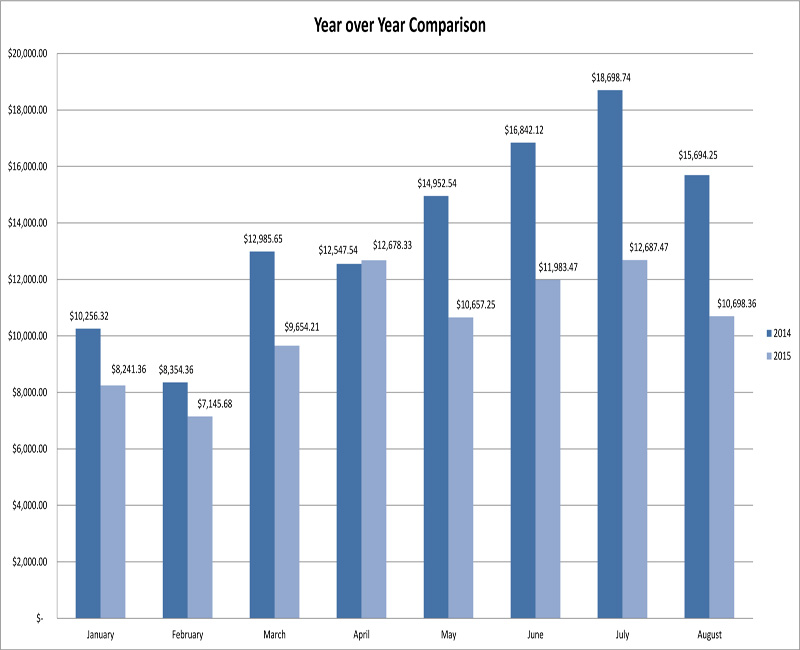

Figure 1 is a typical chart showing a year over year comparison of costs. This is a great tool to monitor monthly costs across your entire fleet but isn't very good to show costs of individual pieces of equipment. To effectively cut repair costs monitoring total expenses isn't enough. Individual costs MUST be monitored and controlled.

Figure 1

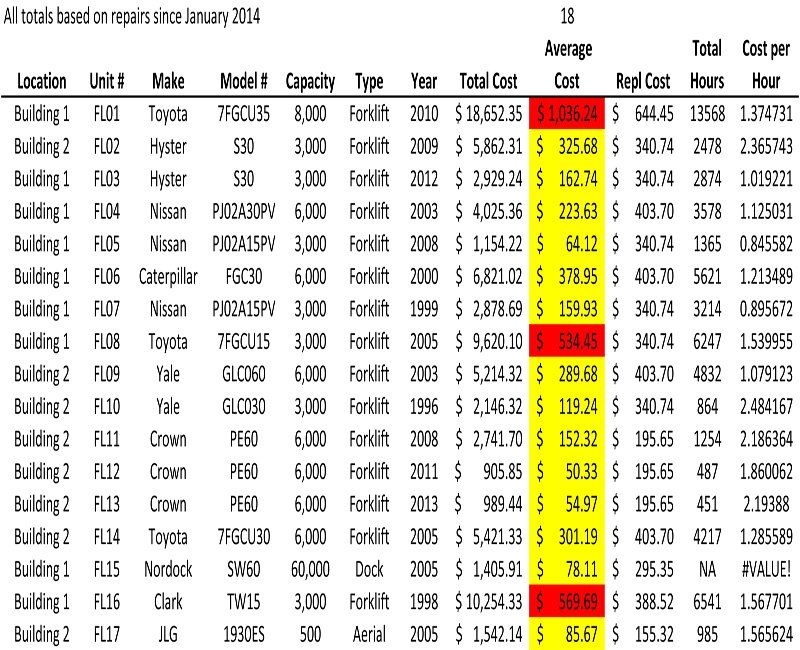

Below (Fig.2) is a breakdown of cost per lift. As you can see there are "flags" that will turn red when the monthly repair cost of a piece of equipment exceeds the replacement cost. Replacement cost would include the monthly lease payment along with a fixed amount for maintenance. The flags turn the cell red so they are easy to identify. Once identified, the repair history of these individual units can be researched and sound decisions can be made about replacement.

Once this report is analyzed it would be easy to determine that FL01, FL08 and FL16 are the highest costing lifts to repair but we can also pull from this data that FL05 and FL10 have very low hours compared to the rest of the fleet. These lifts could possibly be removed (and not replaced) from the fleet or at the very least, switched into another role, possibly with FL08 to reduce overall costs.

Figure 2

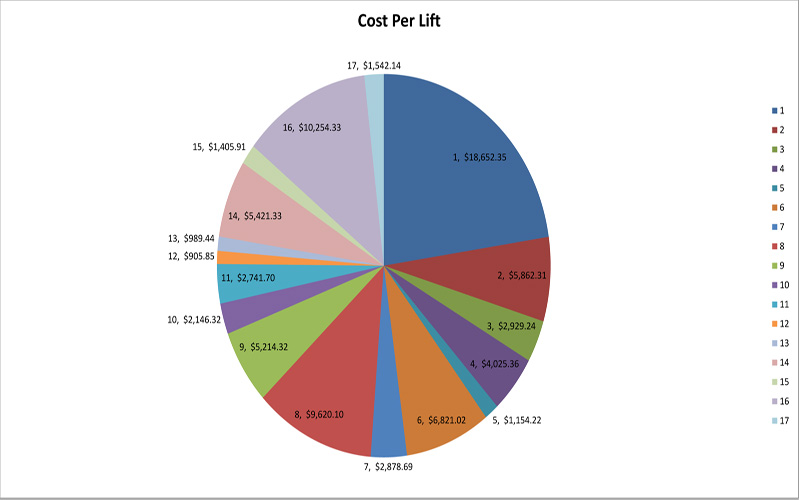

Figure 3 below represents the data in Figure 2 but in a pie chart format. Now, identifying equipment with high repair costs becomes even easier. With a pie chart it's very simple to pick FL01, FL08 and FL16 as the problem lifts. Once problem equipment is identified it's time to start looking at total hours, operator error, number of impacts, individual repairs, major repairs and a host of other parameters that affect the total cost of ownership of these particular pieces of equipment. Only AFTER this thorough investigation can sound decisions be made about replacement of equipment.

Figure 3

Fleet management isn't just about repair costs either. Consider some of the questions below:

- Should I rent or buy?

- Do I have too many forklifts?

- Do I have enough forklifts?

- What is my cost per hour to operate?

- Should I lease or purchase?

- Should I lease with maintenance?

- How often do my lifts need to be PM'd?

- Are my high repair costs due to abuse?

- Do I have the right equipment for the job?

- Are my forklifts OSHA compliant?

There are also a host of other questions that we can provide answers for. Fleet management is our passion. Plus, it's all free with our service! No expensive software/hardware to buy, no expensive consultations with so called "experts", just another value added service with LTS.

Have a questions about our fleet management services? Click here.

Or call us at 717-419-1413.

Again, thanks for visiting and we hope to hear from you soon.